DS FILTER

R&D

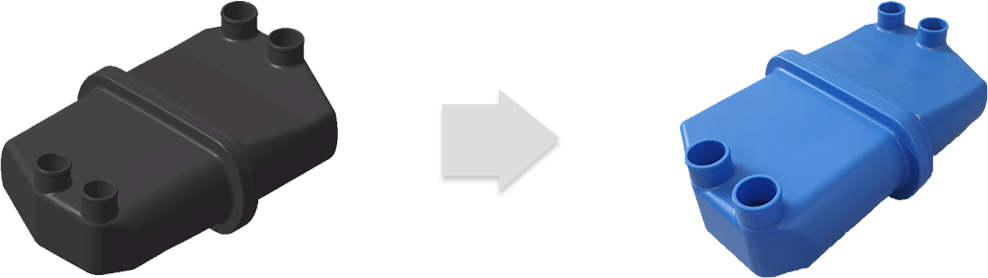

Membrane Humidifier

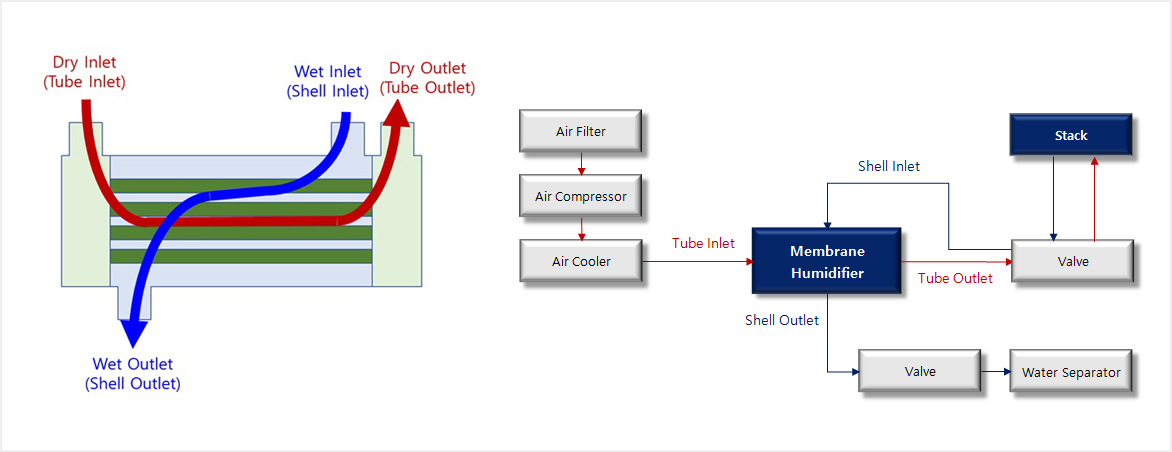

It is a product that improves the durability of the generator and increases the power generation efficiency

by supplying moist air to the generator (Stack) by injecting moisture into the dry air from outside.

Develope the Membrane Humidifier

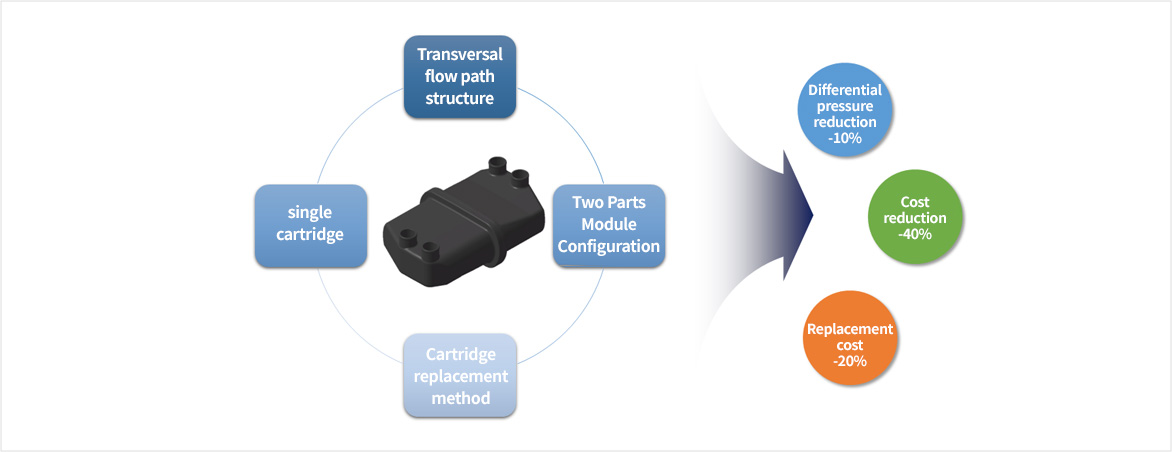

The self-developed membrane humidifier can reduce differential pressure by applying a transverse flow path structure, and has realized cost reduction by reducing the number of single cartridges and module parts. In addition, the cartridge replacement type has the advantage of reducing A/S cost.

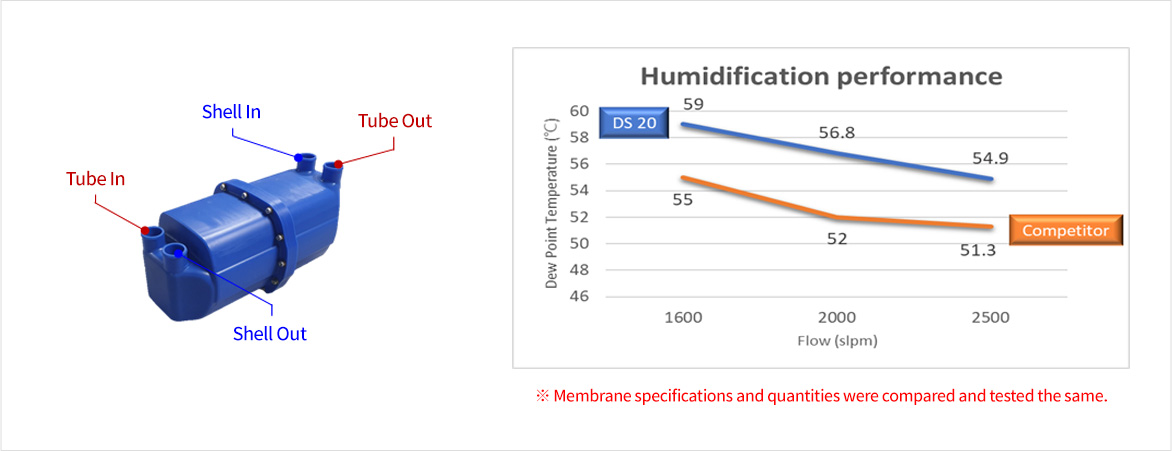

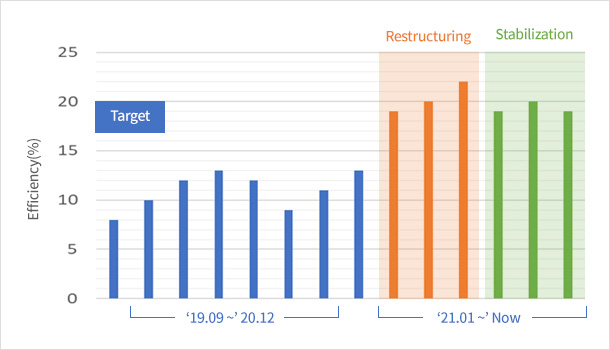

Membrane Humidifier Performance

It was developed to minimize wasted moisture by applying a transversal flow path structure.

As a result, it was verified that the performance was 107% higher even if the same humidifying film was used.

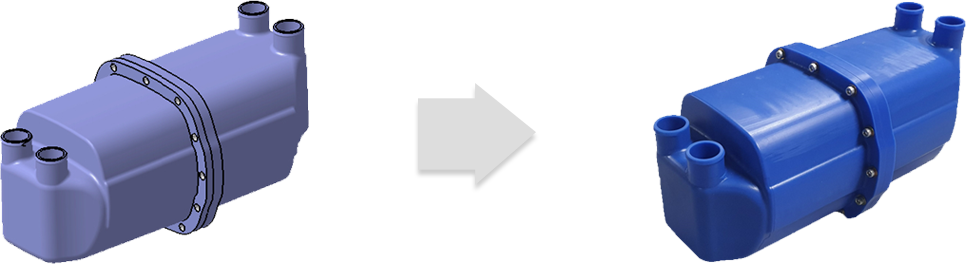

| 1st Development |  |

|---|---|

| 2nd Development |  |

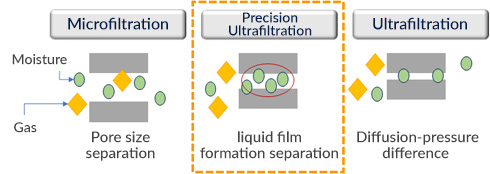

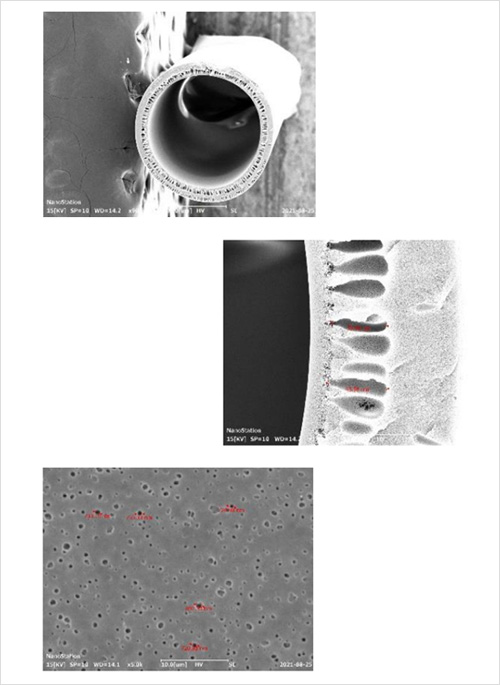

Development of Humidification Film

We have developed “humidification membrane”, a core part of membrane humidifier, to the highest level at home and abroad.

In addition, this technology has been recognized overseas, and we are directly supplying and exporting overseas.

It has micropores to allow various types of gas mixtures to pass through, and separates gases by selective permeation according to the pore size and gas absorption-diffusion mechanism.

Among the many fluids on the outer surface of the membrane, only moisture is selectively absorbed and moved.

| Material | PES | Glass Conduction Ionicity |

173 ℃ |

|---|---|---|---|

| Type | Hollow Fiber | Permeability | < 0.0slpm @0.8barg |

| Outer Diameter | Φ 1.1 | Tensile Force | 0.3 kgf/cm2 |

| Inner Diameter | Φ 0.9 | Burst Pressure | 5barg |

Adhesive Development

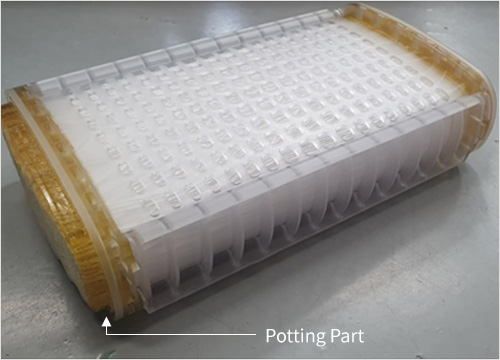

We succeeded in independently developing humidification membranes and potting adhesives, which are key parts of membrane humidifiers, realizing vertical integration of membrane humidifier technology and securing competitiveness through cost reduction.

It has strengths in ductility and chemical resistance and is used for electrical insulators, structural materials, bubble nsulation, and elastic fibers, and can also be used as a substitute for rubber.

We provide potting solutions.

In the electronics industry, potting is the process of filling an entire electronic component with a hard or elastic compound, such as gelatin, to provide resistance to shock and vibration, as well as protection against moisture and corrosion. In the membrane industry, multiple membranes are applied to form a body This is the process of manufacturing the filter by fixing it and maintaining the external airtightness.

| Type | 2 component | Mixing Ratio | 10:8 (Subject : Hardener) |

|---|---|---|---|

| Subject Density | 1.05 ± 0.05 (g/cm3 @25℃) |

Hardener Density | 1.20 ± 0.05 (g/cm3 @25℃) |

| Subject Viscosity | 800 ± 200 (CPS @25℃) |

Hardener Viscosity | 200 ±50 (CPS @25℃) |

| Operating Temperature | 80℃ | Pot Life | 20 ± 5 Min. |

| Curing Humidity | ≤ Relative Humidity 25% | Curing Time | 35 ± 10 Min. |

| Tensile Strength | > 20 MPa | Hardness | 73 ± 5 Shore D |

Ion Filter (under development review)

This product improves system durability and secures user safety by managing conductivity by filtering positive/negative ions in the generator (stack) thermal management system.

Ejector (under development review)

This product minimizes the amount of wasted hydrogen and improves fuel efficiency by reusing once-used hydrogen using the Bentley effect.

Research Performance